![]()

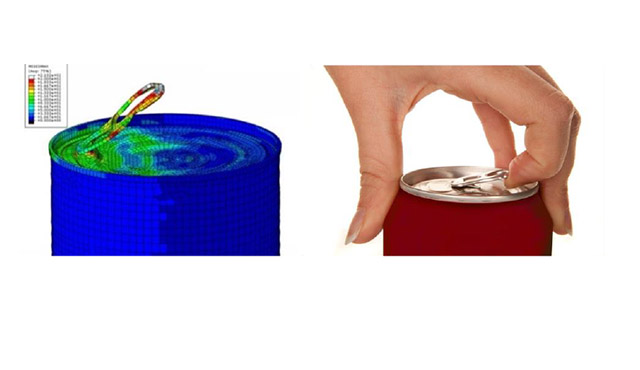

Pack 3.0 uses prototyping software and technology that was originally created to meet the incredibly detailed and exacting standards of the aerospace and automotive industries. We are pioneering the use of this advanced method for testing packaging and, in the hands of our experienced engineers, the potential is remarkable.

This advanced technology can test performance, identify weak spots and investigate improvements to your designs. You’ll not only see what works, but find ways it can work even better.

With Pack 3.0, you’ll be able to make sure packaging meets all functional and technical requirements such as:

Logistical requirements

stacking, pallet transport, shipping.

Production requirements

forming, conveying, filling.

Store shelf requirements

stability, tamper-evidence, drop tests.

CSD container requirements

C02 pressure, creep,.

Consumer use requirements

stability, ease of opening, grip..

Sensitive product container requirements

vacuum, squeeze, pressure.

Please contact us if you’d like to learn more or arrange a demonstration.

PHYSICAL TRIAL

DIGITAL TWIN

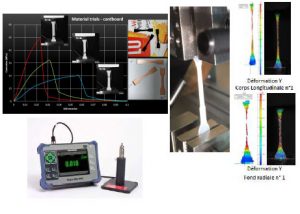

Machine for packaging test and digital simulation validation

Material characterization (all packaging materials)

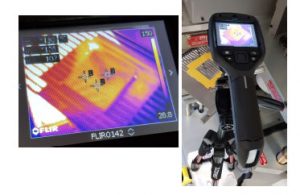

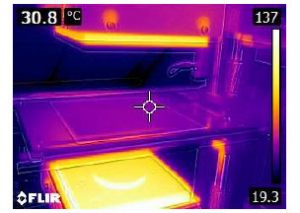

Thermal control chambers

Embedded sensors (Pressure, Temperature)

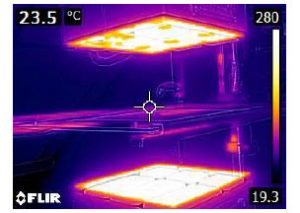

Measuring devices (physical & thermal)

- Flexible

- Small scale production

- Fully instrumented

- Industrial settings

- Scientific

- Support digital simulation programs

A worldwide unique thermoforming pilot machine

Contact plates heating

Infrared heating